During constructions, Maithan Steel Rebars play an important role in complementing the concrete so that the structure can change its shape according to the design of the project being built easily. Due to their high demand in multiple applications during construction, manufacturers of Maithan Steel Rebars aim to produce products with higher strength and better ductility to meet their customers' requirements.

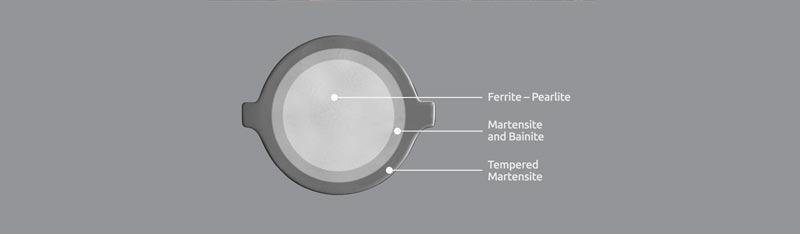

Maithan Steel & Power Ltd. manufactures Maithan Steel Rebars with the latest available HYQST technology, ensuring that the best of products are delivered to our customers.

The high strength Maithan Steel Rebars are the basic requirement for any construction process, be it buildings or bridges. The Maithan Steel Rebar manufactured by us go through stringent quality checks before they reach our customers.

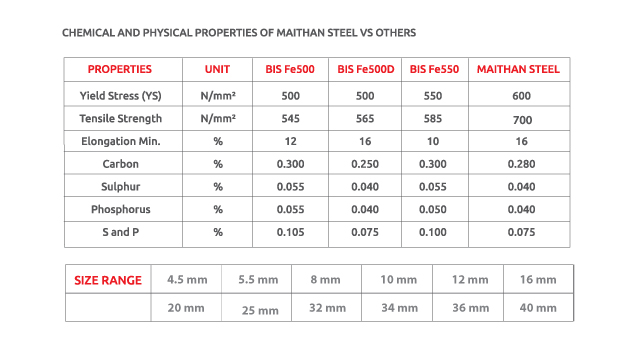

The Maithan Steel Rebars manufactured by us ensure high elongation and thereby better bendability during the construction process. Our high quality Maithan Steel Rebars are built with strength to withstand earthquakes and natural calamities which make them a safe choice for engineers and builders.

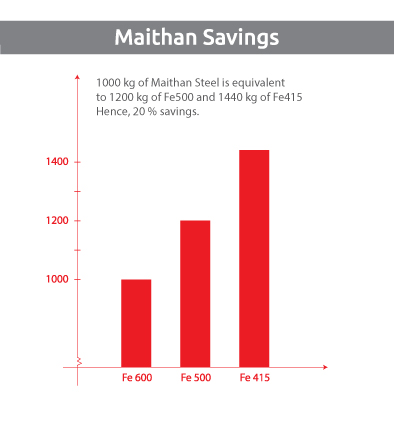

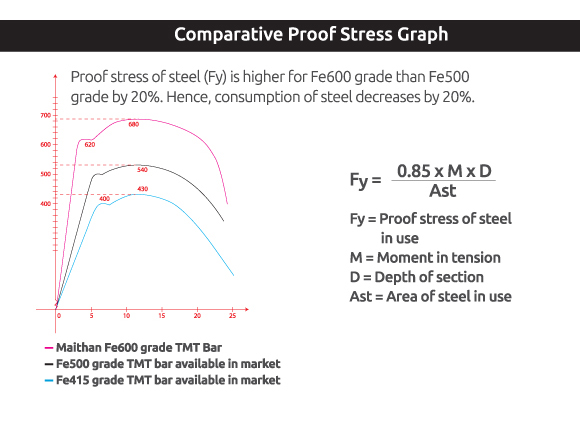

Maithan Steel Rebars offer the STRENGTH of 20, compared to the conventional Fe600 grade available in the market. Usage of high strength Maithan Steel Rebars leads to increased bar spacing as fewer Rebars are required, resulting in reduction in Maithan Steel bar congestion. As less Rebars are required, the construction time is much lesser. Besides consuming less steel, the pillars of the building can be made thinner, thus providing extra space.

Using higher strength Maithan Steel Rebars leads to increased rebar spacing, as fewer Maithan Steel rebars are required.

Due to less consumption of steel, the pillars of the building can be made thinner, resulting in extra space.

As less Maithan Steel Rebars are required, the construction time decreases.

Maithan Steel & Power Limited specialises in the production of high grade steel cross sections, or billets, that have made the Company stand amongst the best manufacturers of steel billets in India.

The billets are used by the construction industry in various hot rolling or cold drawing applications. They are manufactured at our state-of-the-art manufacturing plants using the latest technology. Our manufacturing team ensures that our billets are tested in terms of quality, to ensure that the best quality billets reach our customers. They are the best priced variants available in the market.

At Maithan, we manufacture highly durable Linkon Products - ranging from Steel Repair Plates to Cover Plates. Our products are well-finished and made of heavy-duty stainless steel to guarantee durability.

Mild steel binding wires are needed to keep the Maithan Steel Rebars reinforcements intact during concrete placements. Maithan Linkon is first drawn from rods and then annealed to eliminate stress by providing ductility without compromising on strength. It is flexible, and can be tied easily. It also has the strength to hold the joints in place.

Stirrups are rectangular in shape, and are placed at regular intervals along a column or beam to secure and prevent them from shifting during concrete placements. Maithan Power Ring is made from the strongest TMT Rebars and has 135° bends to prevent it from collapsing under severe forces experienced during earthquakes.

Maithan Steel is indeed a prominent player in India's industrial landscape, particularly in the Iron and Steel segment, with a recent introduction to their product portfolio comprising of Ferro Manganese, Ferro Silicon and Silico Manganese.

Maithan Steel’s commitment to delivering high-quality products tailored to the specific needs of its clients underscores its dedication to excellence and customer satisfaction preceding it's 23 year old legacy of hallmark and trust.

Our manufacturing unit at Purulia is equipped with 2 submerged electric arc furnaces of 9.0 MVA each. Our ferro alloys furnaces are powered by captive power plant consisting of waste heat recovery boilers for green and clean energy at competitive rates

Our mission is to comprehend and cater to customer needs, providing them with the perfect products with consistent quality to forge lasting relationships.

“This expansion marks a significant leap forward in our quest to diversify our offerings, strengthen our market position, and drive sustainable growth.”

The iron and steel industry is undergoing rapid transformation, propelled by changing market dynamics, technological advancements, and evolving consumer preferences. In this dynamic landscape, it is essential for us to not only adapt but also innovate, staying ahead of the curve to meet the needs of our customers and contribute positively to society and the environment.

Our decision to venture into Ferro Alloys production is a strategic one, grounded in our deep understanding of internal consumption, market trends and customer requirements. By integrating this new vertical with our existing iron and steel business, we are not only enhancing our product portfolio but also creating synergies that will enable us to deliver greater value to our customers and stakeholders.

At Maithan Steel, we have always been guided by a commitment to excellence, innovation, integrity, and sustainability. As we embark on this new phase of our journey, these values remain at the core of everything we do. We are determined to uphold the highest standards of quality, safety, and environmental stewardship, ensuring that our operations not only meet regulatory requirements but also set new benchmarks for the industry.

“Our ferro alloys submerged electric arc furnaces are powered by our captive power plant consisting of waste heat recovery boilers for green and clean energy at competitive rates.”

Silicon Manganese, consisting of manganese, silicon, and iron, offers a cost-efficient combination of the mentioned elements, commonly favoured by steel manufacturers. This alloy is widely used in diverse steel products, with particularly elevated usage in stainless steel, alloy steel, and manganese steel.

Ferro Manganese is predominantly composed of manganese and iron, with a significant manganese concentration. It is utilized in steel manufacturing processes where low levels of silicon content are crucial. This alloy is primarily employed in the production of steel, which is integral for flat steel, manganese-rich steel, and stainless steel products.

Ferro Silicon is a composite of silicon and iron, with silicon serving as a potent oxidizer for steel. Maithan Steel's ferro silicon stands out as one of the cleanest options in the market. It finds primary application in speciality steels and is utilized in limited amounts in mild steel. Additionally, Ferro Silicon is employed in the production of silicon, fabrication of silicon steel for electromotors and transformer cores as well as in the manufacturing of corrosion-resistant and high-temperature resistant ferrous silicon alloys.