Maithan Steel & Power Limited is an Integrated State of the art Steel Plant situated at West Bengal; the Manufacturer of 600 Grade TMT Bar from Iron Ore to Finished Product from his own Integrated Steel Plant.

Using Virgin Iron ore deploys high-tech Steel making and refining process at our Integrated Steel Plant.

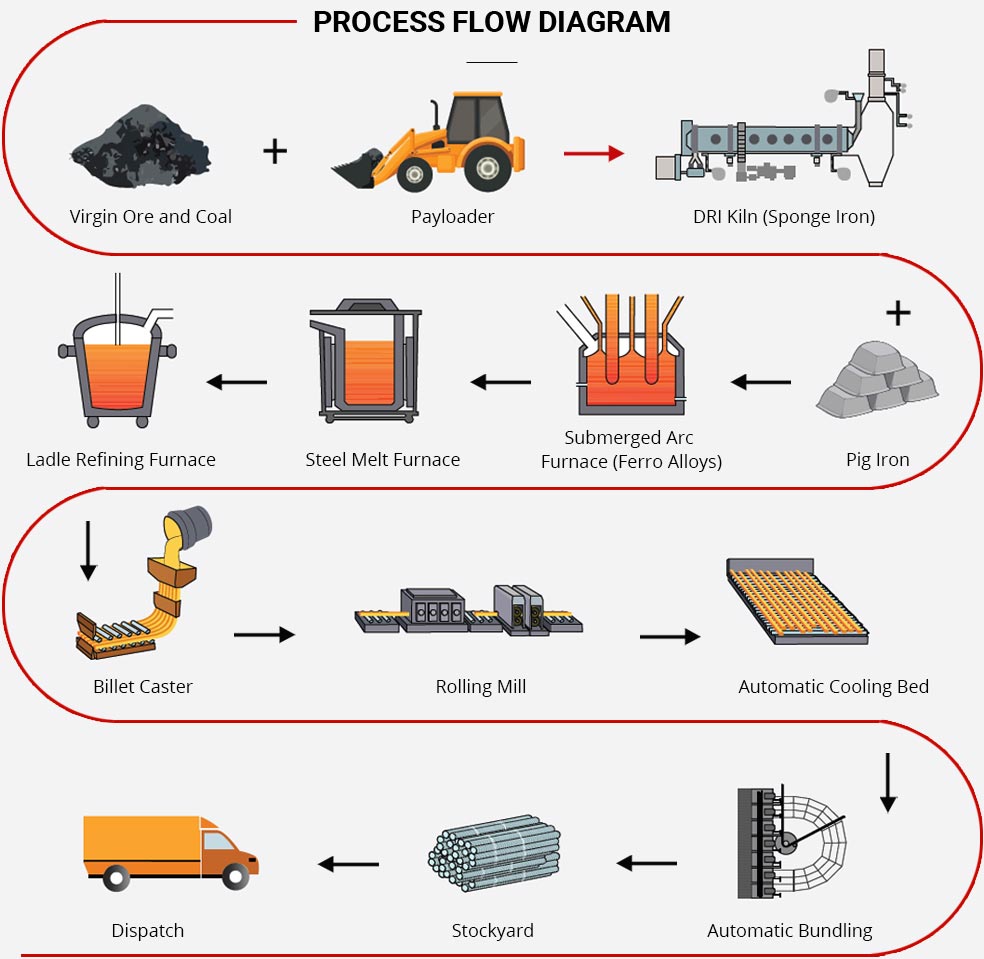

Virgin iron ore and coal is mined, and then shipped to the plant. DRI is a solid-state reduction process of iron ore using coal as a reducing agent at a temperature of 1150 degree Celsius (°C) in Rotary Kilns.

DRI, Pig iron and Ferro alloys are added in furnaces which melt the metals at extremely high temperatures of 1650 degree Celsius. The molten metal, after removal of slag, is taken to LRF (for removal of unwanted Sulphur and Phosphorus) and, fed to Continuous Casting Machine (CCM). Then, the molten and refined steel is solidified into high quality billets.

The C-20 Billets from CCM is directly charged to the High UTS Quenching and Self-Tempering (HYQST) Rolling Mill where it is reduced to Maithan Steel Rebars at 1050 degree Celsius.

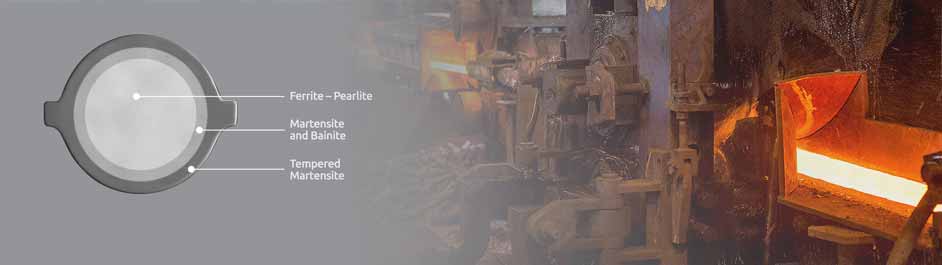

The hot rolled Maithan Steel Rebars are rapidly cooled with RO water through special spray nozzles. This hardens the outer layer of the rebars and helps in the formation of Martensite rim while the core remains hot.

The hot rolled Maithan Steel Rebars are rapidly cooled with RO water through special spray nozzles. This hardens the outer layer of the rebars and helps in the formation of Martensite rim while the core remains hot.

After the rebars leave the quenching station, heat transfers from the hot core to the surface, tempering the outer Martensite rim into Tempered Martensite; an intermediate ring of Martensite and Bainite is also formed.

The Maithan Steel Rebars are cooled slowly on automatic cooling beds, where the core is transferred into a ductile Ferrite - Pearlite structure. The stronger surface with a ductile core gives Maithan Steel 600 its unique characteristic.

With the advent of technology and research, steel has lost its old form of low strength grades and upgraded to more strong and durable forms. This has resulted in higher tensile strength and ductility. Thus, what started as Mild Steel Plain Bars evolved through Deformed Plain Bars, then Cold Twisted Steel Bars (TOR steel) and finally turned to Maithan Steel (Thermo-Mechanically Treated) Rebars.

Maithan Steel Rebars are generally available in the following grades as per IS: 1786-2008: Fe 550D. Recently, the fourth revision of IS 1786:2008 has taken up to incorporate various changes found necessary as a result of experience gained and technological advances made in the field of steel bars and wire manufacturing. Thus a new Grade of Maithan Steel Rebars - Fe 600 has been introduced in the BIS code.

Maithan Group, an industry leader in the steel business, has taken a bold step by introducing Fe600 Maithan Steel Rebars in the Indian Market. With this introduction, heavy demands on steel reinforcement can further be reduced without

compromising on the design standard and planning requirements.

This will prove beneficial for high multi-storied buildings, bridges, fly-overs and other extreme civil engineering structures where large quantities of reinforcement need to be confined in smaller concrete surfaces, resulting in minimum clearances for concrete pouring and compaction.

| MAITHAN Thermo Mechanical Treatment (Maithan Steel) REBARS | OTHERS |

|---|---|

| Uses virgin iron ore and deploys high-tech steel making and refining process at our integrated steel plant. | Reheated ingots or scrap are used leading to no control over physical and chemical properties. |

| Steel is made using DRI + Pig Iron -> SMS -> LRF-Concast -> Hot charging -> Rolling mill. | Use scrap or ingots for steel melting without any secondary refining process, which results in inconsistent chemistry. |

| Maithan Steel Bars are manufactured using High UTS Quenching and Self-Tempering Technology (HYQST). | Outdated rolling process and technology suitable for Fe415 and Fe500 grade. |

| Providing precise and uniform parallel rib pattern engraved through computer controlled CNC notch cutting & branding machines. | Ribs are manually cut resulting in non-uniform rib pattern and weaker bonding. |

| Meets UTS/YS (Ultimate Tensile Strength to Yield Strength) ratio and high percentage elongation. | Old technology leading to high variation in elongation. |

| Uses RO water for Quenching to provide Maithan Steel rebars more consistency, finish and shine. | Uses unprocessed water thereby compromising on quality. |

| Automatic Rolling Mill, Cooling Bed, Cutting and Bending Machines. | Manual process which leads to manufacturing imperfections. |

| State-of-the-art laboratory with high-tech computer aided facilities like Spectrometer and UTM. | Uses conventional testing facilities with low level accuracy and reliability. |

| Maithan Steel Rebars made from in-house high quality billets to enhance the tensile strength under adverse situations. | Made from ingots or commercial billets. |